Did 461 Dean, the "World’s Tallest Modular Building,” Save 20% on Construction? No.

Despite sunny rhetoric claiming phantom gains, the building was misconceived and delayed. Industry observer: "a hard-won lesson in tolerance accumulation."

This is adapted and expanded from a guest post I wrote for TreeHugger, originally published Feb. 22, 2017, under the headline “The World's (Then-)Tallest Modular Building and the Phantom 20% Savings.”

The world's then-tallest modular building opened in late 2016: 461 Dean, part of the Pacific Park (formerly Atlantic Yards) project in Brooklyn, built by developer Forest City Ratner. The pre-construction hype was huge, as Forest City claimed it had "cracked the code" for high-rise modular.

"Applying this R & D to high-rise construction and other markets creates a business opportunity that provides an unparalleled competitive advantage," it told potential partners in a January 2012 Opportunity Brief.

The results were sobering: delays, losses, and a bitter set of lawsuits with former partner Skanska USA, which had been contracted to construct the tower and manage the jointly owned module-assembly factory.

Forest City blamed Skanska's execution; Skanska blamed Forest City's R&D. Both had evidence. Bad luck also delayed production, as Superstorm Sandy swamped the Navy Yard shortly before the launch period. The lawsuits were settled, confidentially, in April 2020, not long before the parties had been scheduled to pursue depositions of key figures, surely a costly process.

The claim of 20 percent savings

Rather than take less than two years to build, thus saving on costs, 461 Dean took nearly four years, and the cost of construction exceeded earlier estimates by 26%. (Also, it would later be well above the building’s sale price.)

Astoundingly, some press accounts claimed that the use of modular techniques, as once promised, allowed Forest City to save 20 percent on the 32-story, 363-unit tower, which contains half market-rate units and half "affordable" ones. Consider:

CNN, Feb. 6, 2017: "Ultimately, the method saved Forest City Ratner Companies about 20% on construction costs.”

Business Insider, Nov. 16, 2016: "That allowed them to save 20% on construction costs, Forest City's VP of residential development, Adam Greene, tells Business Insider."

Architectural Digest, Nov. 17, 2016: "it also cost developers 20 percent less than building a traditional skyscraper."

Bisnow: July 22, 2016: [Forest City's Greene was] "pointing out that building units in a weatherproof factory gave his company a 20% discount and predicting the method would soon be the norm."

It reflects both unskeptical, lazy journalism and a developer brazen even by the standards of real-estate puffery.

Negative benchmarks

Not only did 461 Dean (aka B2) take more than twice as long as expected, it triggered various business setbacks.

As parent Forest City Enterprises (now Forest City Realty Trust) told the Securities and Exchange Commission (see p. 60ff.) in February 2015, they had to buy out the building's 75 percent co-investor, the Arizona State Retirement System. They also recorded a huge $146 million impairment, or write-down in value.

Later in 2015, they had to pay off their tax-exempt bond decades early and fund the rest of construction from equity. The tower, Forest City told the SEC, was once expected to cost $155 million; in late 2016, it estimated $195.6 million, or nearly $539,000 per unit. That’s 26% more.

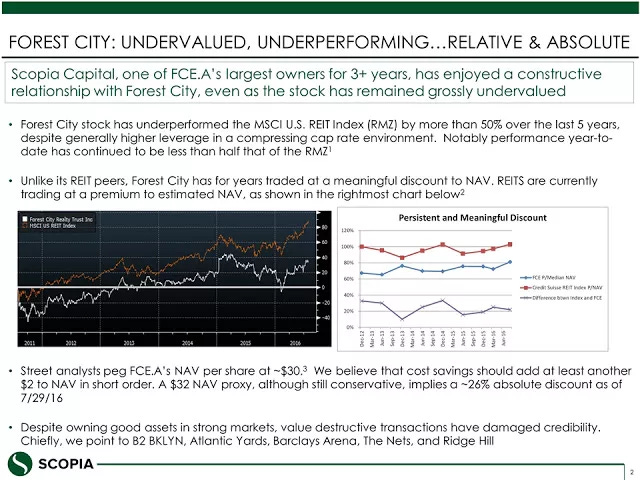

No wonder outside investor Scopia Capital, in a slide presentation filed with the SEC in August 2016 (see below), called 461 Dean (aka B2) a "value-destructive transaction."

Similarly, another investor, Land & Buildings, in a Jan. 20, 2017 press release, counted B2 among the company's most significant losses.

Given that it took Forest City more than twice as long to build the tower as originally promised, you'd think they'd practice some humility. Instead, they portrayed the delay as a mere bump in the road, even though they exited the modular business.

More accuracy, but also spin

Not everyone got it so wrong. Wired Nov. 23, 2016 called the experiment "mixed" and concluded that "The building took more time and money to build than originally promised." National Real Estate Investor Oct. 25, 2016 pronounced, "Those savings didn’t materialize at Dean Street.”

Still, the latter article quoted former Forest City executive Roger Krulak, whose new company Full Stack Modular bought the business (for an unspecified sum): "I would say to [sic] cost of modular construction is 80 percent of the cost of conventional construction.”

Note Krulak's use of conditional language. Indeed, that's how proponents were talking at the start, before the real-world test that proved it wrong. In fact, that figure was more aspiration than guarantee. (More on FullStack—as it’s now known—here.)

Early on, 20 percent was a hope

The potential cost savings, in fact, was always portrayed as conditional.

In November 2011, New York magazine reported that "the whole process is designed to shave as much as 20 percent off construction costs." Fast Company quoted Forest City Ratner CEO MaryAnne Gilmartin as "figur[ing] the modular experiment could potentially shave 10% to 20% off her costs."

John Dolan, a project executive with Skanska, told Curbed, "We estimated that it's around 12 to 15 percent in savings."

Gothamist reported that the builders expected to get faster and thus save more: "As of now, the units are around 10 percent cheaper than their conventional counterparts, though [Forest City's] Melissa Burch... anticipates savings of up to 30 percent as the technique is perfected."

Shifting goals on timing

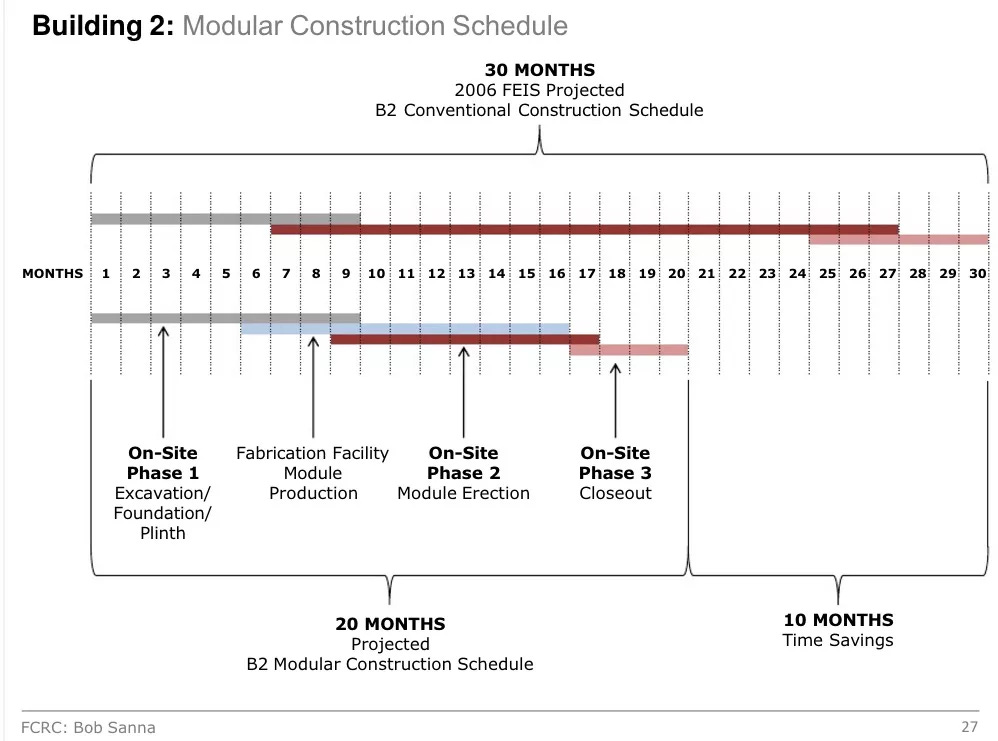

Skanska's Dolan, by the way, said they expected to be finished in 18 months, compared with 24 months for conventional construction. But that benchmark was fuzzy.

At one point, Forest City estimated 18 months, compared with 28 months, then tweaked it to 20 months versus 30 months, as stated publicly in a November 2012 meeting (see below).

Hubris and hype versus reality

The modular story reflects hubris, hype, and an often unskeptical press. Forest City garnered enthusiastic articles in Gizmodo, Gothamist. Fast Company, and Forbes, even as construction was troubled. Krulak, ironically enough, got a Breakthrough Award from Popular Mechanics just as the problems mounted.

The structure suffered leaks, mold emerged, and the first four floors "were largely gutted," a state monitor reported, in documents I acquired through a Freedom of Information Law request.

The builders got so skittish that, on two floors, drywall ceilings and walls were omitted from modules, to be installed later—thus undermining the modular concept. When Forest City announced the start of B2’s 11th floor, after a delay, it announced the need to realign 10th floor modules both horizontally and vertically.

Builders couldn't install wood flooring as planned at the factory, given warranty challenges, so they did so on-site. They did deliver modules with facades attached, unlike some other modular builders, but that didn't work well. So some facades required repair.

Some lessons learned

Now we know more about what went wrong. As Krulak told Wired, the diversity of modules--32 types--meant "we probably went a little overboard on the complexity."

Also, 461 Dean may just have been too tall. Krulak told Fast.Co Design, "Our sweet spot for modular in an urban environment is in the 10-to-18-story, 80,000-to-120,000-square-foot buildings." He told Multi-Housing News his new company would focus on hotels, student housing and multifamily rentals.

Similarly, architect Christopher Sharples of SHoP told Fast.Co Design, in the publication's summary, "After 15 stories, extra brace framing is needed to support the building. Stay under that height, and the building's complexity is significantly less."

Such humility is a far cry from "cracking the code." It should be heeded in any account of 461 Dean's purported savings, as well.

It’s not just framing. The more “tolerance” issues—deviation from a precise fit—the more that accumulates in a taller building.

Modest progress

Since then, FullStack has pursued more modest projects, six to 15 stories, but, as far as I can tell, built only one. (There are other modular companies, of course.)

In 2018, Forest City sold 461 Dean to Iowa-based Principal Global Investors for $156 million, well below the construction cost. While the 461 Dean website claims that the building was “handcrafted locally in the Brooklyn Navy Yard," that, of course, suggests the absence of an actual factory.

That factory, by the way, in April 2023 moved to Hamden, Conn., offering what FullStack called a “more efficient factory with integrated logistics” as well as “the ability to ship modules via truck, rail, and deep-water.”

Nor is 461 the tallest modular building in the world, as once claimed. That's been adjusted, slightly, as "the tallest modular building in the US.”

Mixed lessons

Some still hail the project. Modular construction consultant Joshua McShanog praised the project in a Jan. 2, 2023 LinkedIn post:

Overall, the modular construction project at 461 Dean Street is an exciting and innovative development that has helped to pave the way for the use of prefabricated modular units in high-rise buildings. The projects goal was to set a new standard for sustainable and efficient construction, and could potentially serve as a model for similar projects in the future.

(Note that the LinkedIn post credits “modular specialist Full Stack Modular,” but the latter company purchased the modular factory only after Forest City had completed construction of 461 Dean.)

McShanog’s enthusiasm mostly drew assent, but one modular construction veteran, Julian Bowron, pushed back, writing:

The 461 Dean project was not a construction success. It is a hard-won lesson in tolerance accumulation.

Assembly of modules in 2013 stalled at the 8th floor due to tolerance accumulation, which could be seen from the street. They sat, soaking up the rain for over a year. During which time the GC, Skanska and Forest City Ratner had a good go in court.

Bowron went on the explain how the building had been rescued, adding:

The lesson learned: If modules and the steel frame they are tied in to have tolerances of +- 1/8", after 8 floors, adjacent stacks can be out of level and plumb by as much as 2". So the building flares like a bunch of flowers in a vase.

The debate continued about whether the project serves as a proving case for high-rise modular. What’s not debatable, however, is that some boosters have overlooked the truth.

Great insights, thank you.

I deal with stacking tolerances on occasion in manufacturing. The more things that have to precisely fit into each other, the more “interesting” life gets. Or, you do it like one factory I visited where everything was hand-drilled on the assembly line and no two appliances ever left the plant quite alike.

Thank you for revisiting this Norman and I hope you are well.